Medical Industry

-

Medical Cabinet With Glass Doors and Lockable | Youlian

1.High-quality metal cabinet designed for secure and organized storage of pharmaceuticals and medical supplies.

2.Features upper glass-paneled doors for easy viewing and inventory of stored items.

3.Lockable compartments and drawers to ensure restricted access and safeguard sensitive medical supplies.

4.Durable, corrosion-resistant metal construction ideal for hospitals, clinics, and laboratories.

5.Multiple shelving options for efficient storage and organization of various types of medical supplies.

-

Secure Locking Steel Medical Storage Cabinet | Youlian

1. Medical Storage Solution: Designed for storing medical supplies, instruments, and medications securely in healthcare settings.

2. Durable Construction: Made from high-quality steel, ensuring long-term reliability and resistance to wear.

3. Secure Locking: Equipped with a high-security locking system to safeguard sensitive medical items.

4. Adjustable Shelves: Features adjustable shelving to accommodate various sizes of medical supplies.

5. Space-Saving Design: Compact yet spacious, maximizing storage while maintaining a small footprint.

-

UV Sterilization Endoscope Dry Storage Cabinet | Youlian

1. A high-tech cabinet designed for endoscope drying and sterilization.

2. Equipped with UV sterilization technology for thorough disinfection.

3. Designed to meet stringent medical hygiene standards.

4. Spacious design with dual compartments for efficient storage.

5. Mobile and easy to integrate into hospital and clinic workflows.

-

Multi-Compartment Storage Medical Cabinet | Youlian

1. High-quality steel construction for durability and long-term use. 2. Multiple compartments with a combination of glass doors, drawers, and lockable cabinets. 3. Designed for medical and office applications requiring secure storage. 4. Easy to clean, corrosion-resistant surface for hygienic environments. 5. Ideal for storing medical supplies, documents, or personal belongings.

-

Medical Instrument Cabinet Hospital Stainless Steel medical cabinet for hospital | Youlian

Medical Instrument Cabinet Hospital Stainless Steel medical cabinet for hospital, a reliable and durable storage solution designed to meet the specific needs of healthcare facilities. This high-quality cabinet is built to provide secure and organized storage for medical instruments and supplies, ensuring easy access and efficient management of essential medical equipment.

Constructed from premium stainless steel, this medical cabinet is built to withstand the demanding environment of a hospital setting. The robust material not only offers exceptional durability but also provides resistance to corrosion, making it an ideal choice for maintaining a hygienic and sterile storage environment for medical instruments.

-

Durable and Versatile Oxygen Concentrator Metal Cabinet | Youlian

1.High-Quality Construction: Made from premium-grade steel for maximum durability.

2.Advanced Design: Engineered for optimal functionality and aesthetic appeal.

3.Secure Housing: Provides robust protection for internal components of the oxygen concentrator.

4.Customizable Options: Available in various sizes and finishes to meet specific requirements.

5.Easy Access and Maintenance: Designed with accessibility in mind for easy servicing and upkeep.

-

Stainless steel medicine storage cabinet hospital pharmacy chemical storage cabinet | Youlian

1.Constructed from premium-grade stainless steel for maximum durability and resistance to corrosion.

2.Designed for secure storage of medicines, chemicals, and medical supplies in hospital or pharmacy environments.

3.Double-door upper cabinet with glass windows for easy viewing of contents.

4.Spacious lower cabinet and drawers for organizing supplies and equipment.

5.Lockable compartments ensure security and compliance with medical regulations.

6.Customizable in size and color to meet specific space and storage needs.

-

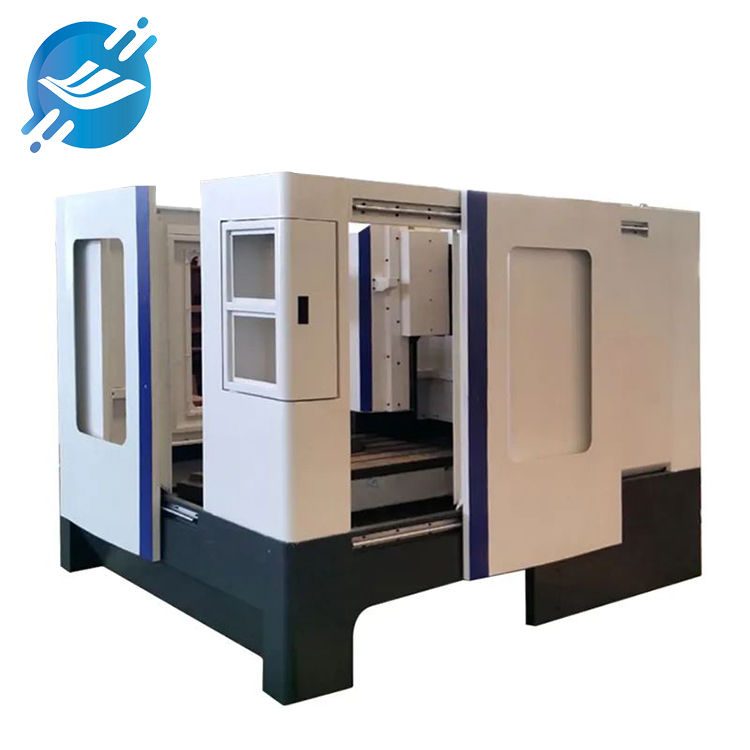

Customized Movable Industrial Metal Tool Cabinet Outer Case for Automation Machine | Youlian

1. Made from high-quality stainless steel for maximum durability.

2. Designed for outdoor and industrial use, providing robust protection against harsh environments.

3. Weather-resistant with superior sealing to protect internal components.

4. Equipped with a secure locking mechanism for enhanced safety.

5. Versatile design suitable for various electrical control needs.

-

High-Capacity Ozone Disinfection Cabinet Metal Outcase for Comprehensive Sterilization | Youlian

1. Premium Metal Outcase Design: Robust and durable for long-term use.

2. Advanced Ozone Disinfection Technology: Ensures thorough sterilization.

3.High-Quality Stainless Steel Construction: Provides excellent resistance to wear and corrosion.

4.Large Internal Capacity: Suitable for various applications.

5.User-Friendly Interface with Digital Controls: For easy operation and monitoring.

-

Premium Stainless Steel Disinfection Box Metal Cabinet | Youlian

1.Robust Construction: Crafted from high-grade stainless steel for enhanced durability.

2.Sleek Design: Modern, professional appearance suitable for various settings.

3.Protective Housing: Provides secure and safe housing for internal disinfection components.

4.Accessibility and Maintenance: Designed for easy access and maintenance.

5.Customizable Features: Available in different sizes and configurations to meet specific needs.

-

Medical apparatus and instruments storage metal hospital cabinet

Short Description:

1. Made of 304 stainless steel plate material

2. Thickness: 0.5-1.2mm

3. The medical cabinet is easy to disassemble and assemble, has a solid structure and is durable.

4. The original color of stainless steel.

5. Surface treatment: brushed

6. Dust-proof, moisture-proof, corrosion-proof and theft-proof

7. Strong load-bearing capacity, with casters for easy movement

8. Two double doors are embedded in transparent acrylic for easy access.

9. Application areas: schools, gymnasiums, public places, staff rooms, offices, laboratories, hospitals

-

High precision & high quality mechanical testing equipment sheet metal casing | Youlian

1.The material of the test equipment shell isgenerally aluminum, carbon steel, low carbon steel, cold rolled steel, hot rolled steel, stainless steel, SECC, SGCC, SPCC, SPHC, and other metals. It mainly depends on the needs of the customer and the quality of the product. Functional decision.

2.Material thickness: generally between 0.5mm-20mm, depending on the customer’s product needs

3.Welded frame, easy todisassemble and assemble, strong and reliable structure

4.The overall coloris gray, white, etc., which can also be customized.

5.The surface is processed through ten processes including degreasing – rust removal – surface conditioning – phosphating – cleaning – passivation. It also requires powder spraying, anodizing, galvanizing, mirror polishing, wire drawing, and plating. Nickel and other treatments

6.Application fields: Smart device shells are indispensable in modern industrial production processes and are often used in machinery, automation, electronics, communications, medical equipment and other fields.

7.There is a door lock setting for high security.

8.KD transportation, easy assembly

9.There are heat dissipation holes to prevent the temperature from being too high.

10.Accept OEM and ODM