Raw material

With the continuous improvement of people's living standards, the application of sheet metal enclosures is becoming more and more extensive.The more raw materials we use for production are cold-rolled steel (cold plate), galvanized sheet, stainless steel, aluminum, acrylic and so on.

We all use high-quality materials, and do not use inferior raw materials for production, and even some imported raw materials. The purpose is to just want the quality to be so good that it is moving, and the resulting effect meets expectations and meets the requirements.

Production Process

Laser cutting machine

Laser cutting machine is the energy released when the laser beam is irradiated on the surface of the workpiece to melt and evaporate the workpiece to achieve the purpose of cutting and engraving. Smooth, low processing cost and other characteristics.

Bending machine

The bending machine is a mechanical processing tool. The bending machine uses the matching upper and lower molds to process the flat plate into workpieces of different shapes and angles through different pressure sources.

CNC

CNC production refers to the automatic production of numerical control. The use of CNC production can improve production accuracy, speed, processing technology and reduce labor costs.

Gantry milling

The gantry milling machine has the characteristics of high flexibility and process compounding, which breaks the traditional process boundaries and separate processing procedures, and can greatly improve the utilization rate of equipment.

CNC punch

The CNC punching machine can be used for the processing of various metal thin plate parts, and can automatically complete a variety of complex pass types and shallow deep drawing processing at one time.

Technical Support

We have a number of machines and equipment, including laser machines and bending machines imported from Germany, as well as a number of professional technical engineers.

| No | Equipment | Q'ty | No | Equipment | Q'ty | No | Equipment | Q'ty |

| 1 | TRUMPF laser machine 3030 (CO2) | 1 | 20 | Rolling maching | 2 | 39 | Spoting welding | 3 |

| 2 | TRUMPF laser machine 3030 (Fiber) | 1 | 21 | Press riveter | 6 | 40 | Auto nail welding machine | 1 |

| 3 | Plasma cutting machine | 1 | 22 | Punching machine APA-25 | 1 | 41 | Sawing maching | 1 |

| 4 | TRUMPF NC punching machine 50000 (1.3x3m) | 1 | 23 | Punching machine APA-60 | 1 | 42 | Laser pipe cutting machine | 1 |

| 5 | TRUMPF NC punching machine 50000 with auto Ifeeder & sorting function | 1 | 24 | Punching machine APA-110 | 1 | 43 | Pipe cutting machine | 3 |

| 6 | TRUMPF NC punching machine 5001 *1.25x2.5m) | 1 | 25 | Punching machine APC-1 10 | 3 | 44 | Polishing machine | 9 |

| 7 | TRUMPF NC punching machine 2020 | 2 | 26 | Punching machine APC-160 | 1 | 45 | Brushing machine | 7 |

| 8 | TRUMPF NC bending machine 1100 | 1 | 27 | Punching machine APC-250 with auto feeder | 1 | 46 | Wire cutting maching | 2 |

| 9 | NC bending machine (4m) | 1 | 28 | Hydraulic press machine | 1 | 47 | Auto grinding machine | 1 |

| 10 | NC bending machine (3m) | 2 | 29 | Air compressor | 2 | 48 | Sand blasting machine | 1 |

| 11 | EKO servo motors driving bending machine | 2 | 30 | Milling machine | 4 | 49 | Grinding machine | 1 |

| 12 | Topsen 100 tons bending machine (3m) | 2 | 31 | Drilling machine | 3 | 50 | Lathing machine | 2 |

| 13 | Topsen 35 tons bending machine (1.2m) | 1 | 32 | Tapping machine | 6 | 51 | CNC lathing machine | 1 |

| 14 | Sibinna bending machine 4 axis (2m) | 1 | 33 | Nailing machine | 1 | 52 | Gantry milling machine *2. 5x5m) | 3 |

| 15 | LKF bending machie 3 axis (2m) | 1 | 34 | Welding Robot | 1 | 53 | CNC milling machine | 1 |

| 16 | LFK grooving machine (4m) | 1 | 35 | Laser welding maching | 1 | 54 | Semi-auto powder coating machine (with environment assessment certification) 3. 5x1.8x1.2m, 200m long |

1 |

| 17 | LFK cutting machine (4m) | 1 | 36 | Submerged arc welding machine | 18 | 55 | Powder coating oven (2 8x3.0x8.0m) | 1 |

| 18 | Deburring machine | 1 | 37 | Carbon dioxide protection welding machine | 12 | |||

| 19 | Screw pole welding machine | 1 | 38 | Aluminum welding machine | 2 |

Quality Control

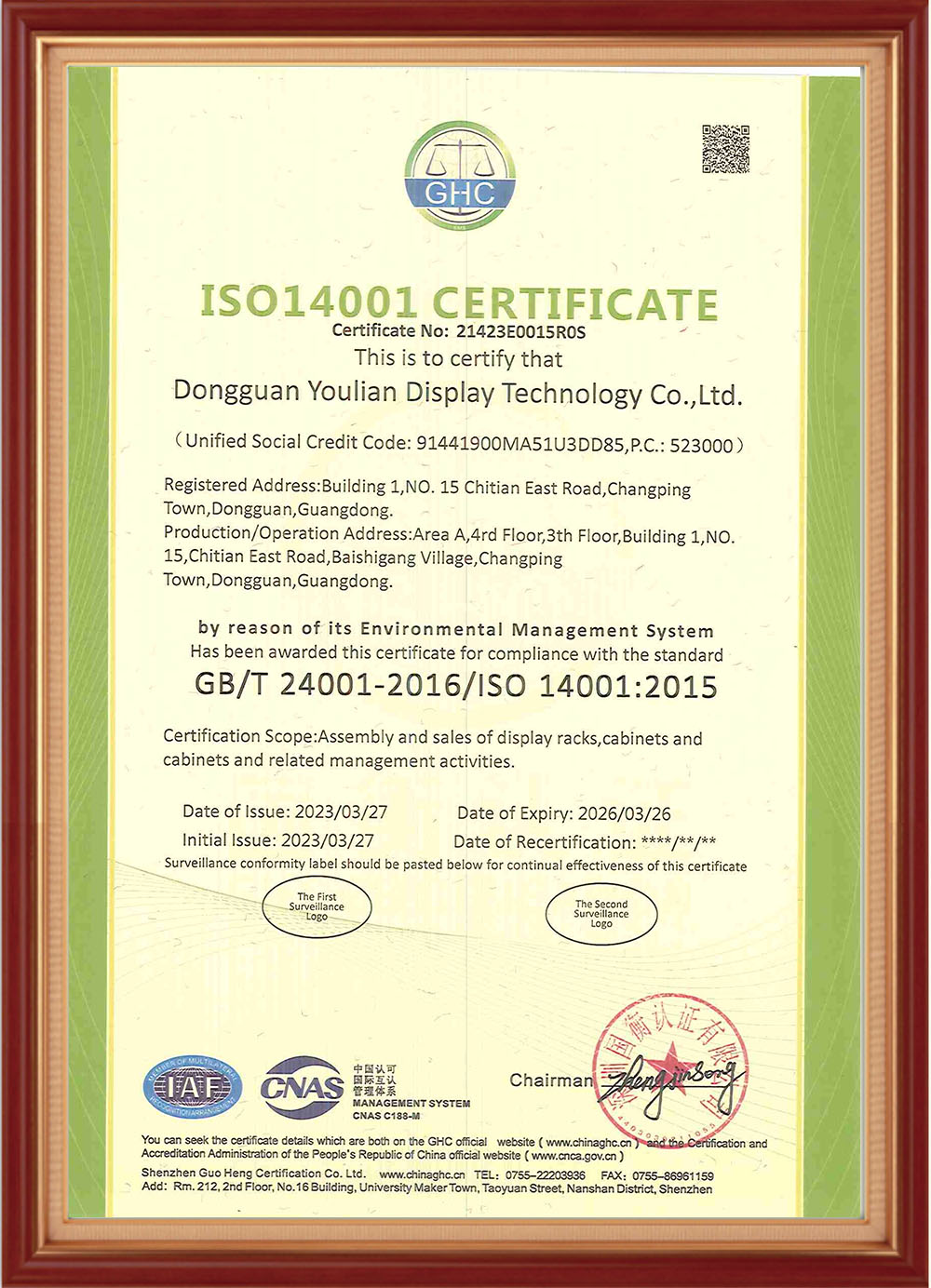

Fully committed to providing OEM /ODM customers with the best quality products and services, fully implements the ISO9001 quality system and strictly implements three inspections in production, namely raw material inspection, process inspection, and factory inspection. Measures such as self-inspection, mutual inspection, and special inspection are also adopted in the production circulation process to ensure product quality. Ensure that non-conforming products do not leave the factory. Organize production and provide products in strict accordance with user requirements and relevant national standards to ensure that the products provided are new and unused products.

Our quality policy, embedded in our mission and high-level strategies, is to consistently exceed our customer's requirements for quality and create long-term customer loyalty. We continually review quality objectives with our teams and improve our Quality Management Systems.

Focus our efforts toward superior customer satisfaction.

Understand customers' business needs.

Provide superior customer defined quality and service.

Consistently satisfy and exceed customers' requirements for quality and provide "an exceptional buying experience" on each purchase to create long-term loyalty.

In order to verify whether various items in the production process meet the specified requirements, the inspection and test requirements are specified, and records must be kept.

A. Purchase inspection and test

B. Process inspection and test

C. Final inspection and test